IN EVIDENCE

Video Library

A video which shows the features and performance of the STIFERITE Class SK panel and its application methods within the ETICSystem is available

main partner

The use of STIFERITE Class SK panels does not require special instructions nor any particular changes to the application and mounting systems described in the CORTEXA manual, which should be referred to for a comprehensive description of the application procedures for the entire system. The laying methods are also shown in "The STIFERITE Class SK exterior insulation system" video.

Types of supports and preliminary checks

The STIFERITE Class SK exterior insulation system can be installed on all building substrates with a good continuity and bearing capacity: brick walls, blocks, panels or concrete walls, tuff, outdoor wood, etc.

A damage and support resilience inspection must be carried out particularly in restructuring cases and, should this require a recovery, a primer must be laid or the substructure must be roughened.

The following conditions must always be verified by expert installers:

1. the surface must be coplanar and not show excessive unevenness

2. the surface must be clean from any dust and residues

3. the support should not be overly absorbent

4. the surface must be dry

5. the support must show no permanent rising damp phenomena.

Cutting the panels

The STIFERITE Class SK panels can be cut or trimmed with a cutting tool blade (hacksaw rigid blade, circular saws), but cannot be cut by hot wire.

Fastening methods

Bead or spot (recommended) round the edges fastening method

Ray the glue around the edges (bead) and two or three gluing points at the centre of the panel, so that by pressing the insulating plate at the bottom, and respecting the admissible support tolerances, a 40% minimum glue coverage is obtained.

Ray the glue around the edges (bead) and two or three gluing points at the centre of the panel, so that by pressing the insulating plate at the bottom, and respecting the admissible support tolerances, a 40% minimum glue coverage is obtained.

Entire surface method

The glue can be applied to the insulating panel with a notched trowel (with variable teeth according to the evenness of the support). This bonding system is only possible for sufficiently planar supports.

Laying and fastening the STIFERITE Class SK panels

The STIFERITE Class SK panels must be laid in horizontal rows, from the bottom upwards, with half-bond patterns. The heads of the panels must be alternated in the corners.

The STIFERITE Class SK panels must be laid in horizontal rows, from the bottom upwards, with half-bond patterns. The heads of the panels must be alternated in the corners.

The panels must be perfectly matched and there should be no gaps greater than 2 mm. Should these be present, they must be sealed with strips of insulating material or filled with single-component polyurethane foam.

After careful installation, the surface of the panels must be planar. Otherwise, any irregularities of the panels’ surface must be smoothed with abrasive paper. The possible abrasion may remove areas not exceeding 30 cm. The dust produced by the sanding operation must be taken away.

The polyurethane foam on the edges of the panels not protected by the coating tends to turn yellow due to UV rays: the powdery substance produced (yellowish) must be completely removed by sanding and brushing before applying the base-coat.

The scratch plaster coat must be applied according to instructions in the Cortexa manual and with the nominal thicknesses provided by the manufacturer.

Tessellation

The STIFERITE Class SK thermal exterior insulation system envisages the tessellation of the panels and may only be carried out after the glue has completely hardened (at least 48 hours).

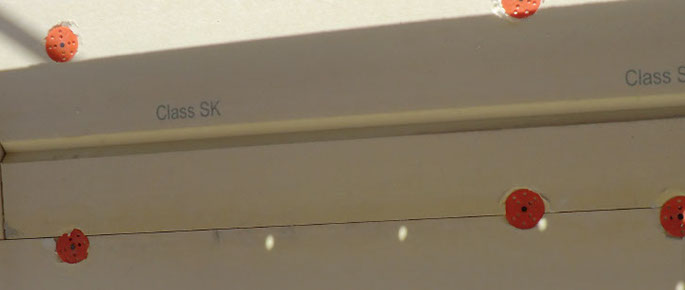

The anchors must comply with ETAG 014 requirements. The typology choice should be made by considering the substrate features (gravel, concrete, wood,...), the plaster and possibly the putty and the flatness of the anchoring substructure in order that the fastening is appropriately resistant to tearing. We recommend 60 mm diameter hammer, screw anchors or toggles for STIFERITE Class SK panels. The height, orientation and typical wind strength in the area where the building is located defines the required amount of hardware with an anchor load of 0.2 or 0.15 kN (see Eurocode I).

The most common fastening scheme is the illustrated "T" one, which requires fastening each panel at the corners and in the centre (6 fastening points//m2).

The most common fastening scheme is the illustrated "T" one, which requires fastening each panel at the corners and in the centre (6 fastening points//m2).

Base-coat plaster and reinforcement

The base-coat plaster is applied by hand or machine to the insulating layer in the thicknesses specified by the manufacturer and the stiffened fibre glass mesh is inserted vertically from top to bottom, with an overlap between the sheets of at least 10 cm whilst avoiding the formation of any folds. The mesh should be positioned in the centre or in the outer third of the base-coat plaster. The finishing coat is applied with the "wet on wet" method in order to ensure the necessary coverage of the entire mesh.

The glass fibre mesh must be covered with at least a 1 mm layer of mortar, and of at least 0.5 mm in the mesh overlap areas.

Finishing coat plaster

After the base coat plaster is hardened, in accordance with the manufacturer’s instructions, and with the appropriate weather conditions, the finishing coat may be applied; this must be laid over a base-coat where indicated by the system manufacturer's manual.

Site Map | Privacy Policy | Cookie Privacy | Disclaimer

© Stiferite SpA a socio unico - Viale Navigazione Interna 54/5 - 35129 Padova

P.IVA 03647120280 - REA PD 325913 - Cap. Soc. € 7.737.000 i.v.